Viscosity might sound like a complex term, but it’s simply how thick or thin a liquid is, and if you’re dealing with engine oils, altering viscosity can mean the difference between a well-oiled machine and a costly breakdown. Diving into ‘what is viscosity and how to improve it’ uncovers ways to refine your oil’s performance for both cold starts and high-temperature conditions. Let’s get a handle on the flow of things, why viscosity matters, and how you can fine-tune it for your engine’s needs.

Shop for the products in this blog

Key Takeaways

Viscosity measures a fluid’s resistance to flow and is critical for determining the efficiency and protection provided by the lubricating film of engine oils, which varies with temperature.

Improving oil performance can be achieved through viscosity index improvers that stabilize oil over temperature changes and by choosing synthetic oils for their superior stability and reduced need for improvers.

Selecting the appropriate oil viscosity is vital for engine health, ensuring optimal lubrication across different temperatures and conditions, which directly impacts engine longevity and efficiency.

Decoding Viscosity: The Science of Oil Flow

For those unfamiliar with technical terminology, viscosity is essentially a measure of how a fluid resists flow. This characteristic significantly influences the fluid’s behavior and how it moves. Imagine pouring honey and water from separate containers. The slow flow of honey indicates that it has a higher viscosity compared to water. This difference in viscosity affects the way each substance moves and behaves. Now, consider this in terms of motor oil. The viscosity of engine oil reflects how easily it pours at a specific temperature. But why is this important?

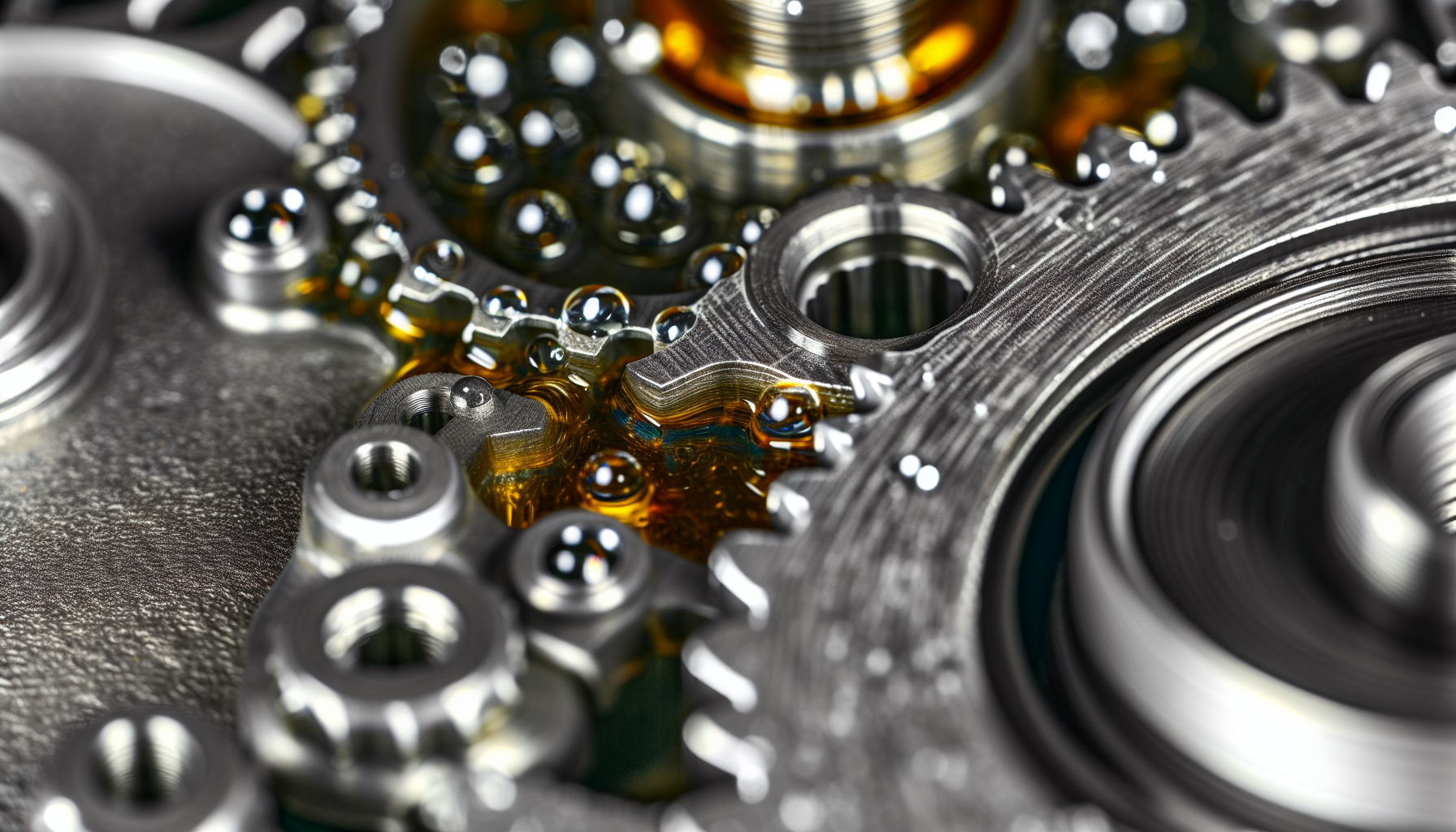

Well, the viscosity of the oil is critical in determining the thickness of the lubricating film it forms. This film prevents metal-on-metal contact in the engine, directly impacting its efficiency and protection. However, oil viscosity isn’t constant; it changes with temperature. Lubricants with a low viscosity index experience rapid viscosity decreases as temperature rises, which can lead to insufficient lubrication. Enter the viscosity index (VI), a measure that indicates the extent to which an oil’s viscosity is affected by temperature changes. Meeting the engine’s operational temperature requirements is of utmost importance for oil.

Defining Viscosity in Motor Oils

In the context of motor oils, viscosity becomes a bit more complex. Oil viscosity explained in this context is not only about the resistance to flow but also how the oil resists shearing forces. This resistance is vital in maintaining the strength of the oil film between engine parts across different temperatures, preventing wear and tear.

Measuring viscosity involves methods like using a rotary viscometer, which rotates a spindle in the oil and measures the required torque. Grasping and measuring motor oils’ viscosity is vital for guaranteeing the oil’s performance in forming a protective lubricating film that safeguards engine components under diverse conditions.

Understanding Kinematic and Dynamic Viscosity

Speaking of viscosity, we generally refer to two main types: dynamic viscosity and kinematic viscosity. Dynamic viscosity, or absolute viscosity, represents the internal friction within the oil, indicating the resistance to flow under pressure. It’s crucial for understanding the fluid resistance within machinery and engines.

On the other hand, kinematic viscosity considers the rate of oil flow under the influence of gravity. So while dynamic viscosity contributes to the oil’s resistance to flow and shear, kinematic viscosity provides a perspective on how gravity affects the oil’s flow. Both these measures play a pivotal role in comprehending and improving the performance of engine oils.

Enhancing Viscosity: Methods to Improve Oil Performance

Having grasped the concept of viscosity and its significance, we can now explore ways to enhance it to boost oil performance. The right viscosity grade of oil enables efficient heat transfer, helping to keep the engine at optimal operating temperatures and preventing overheating.

You might wonder how to ascertain the correct oil viscosity grade. The solution hinges on viscosity index improvers and the selection between synthetic and conventional oils.

Viscosity Index Improvers

Viscosity index improvers (VIIs) are polymer additives that help stabilize the viscosity of lubricants across different temperatures without necessarily increasing the base viscosity of the oil. These additives enhance the low viscosity lubricants’ thickening efficiency at elevated temperatures. This allows the lubricants to sustain their performance over a wider temperature range. So, oils with a higher viscosity index, often due to the use of VIIs, are less affected by temperature changes, ensuring stable viscosity across broad temperature ranges, crucial for engine performance.

Nonetheless, achieving equilibrium between efficient thickening and polymer stability under mechanical shear stresses is of paramount importance. Higher molecular weight polymers are more effective at thickening but less stable under shear. Thus, the use of VIIs offers several benefits:

Extends the service life of lubricating oils

Supports operation over a wider temperature range

Contributes to the longevity of machinery

Reduces energy consumption

Synthetic vs. Conventional Oils

On the other hand, we have the choice between synthetic and conventional oils. Synthetic oils offer several advantages over conventional oils, including:

Higher viscosity stability, reducing the need for viscosity index improvers

More stable viscosity across a wide range of operating temperatures

Resistance to thinning at high temperatures

These benefits make synthetic oils a popular choice for many applications.

Conventional oils, typically mineral-based, can lose effectiveness at high temperatures due to reduced viscosity, necessitating the use of VIIs to maintain a protective lubricant film. As oil flows, synthetic oils, made from more advanced refining processes, result in higher purity and tailored molecular structures for optimal engine performance.

The Role of Viscosity in Engine Health

Until now, we have gained insights into the concept of viscosity, its measurement, and methods to enhance it. Now, let’s discuss the role viscosity plays in engine health. The viscosity of engine oil is crucial in forming a protective film between moving parts, which minimizes friction and reduces wear.

Decreasing mechanical friction is a key benefit of choosing the right viscosity grade, which aids in maintaining efficient energy consumption, a key factor for engine longevity and performance.

Low Temperature Viscosity and Engine Start-Up

Using the right viscous oil becomes particularly important in cold conditions. Low ambient temperatures can significantly affect the flow characteristics of lubricants, leading to high startup torque and potential failure to start the engine.

Lower viscosity oils promote easier flow at low temperatures, ensuring proper lubrication during cold starts, and automotive engines can start at low temperatures down to -25°F with the help of such multigrade oils.

High Temperature Viscosity and Engine Load

On the other end of the temperature spectrum, high-temperature viscosity becomes significant. At high temperatures, a higher viscosity oil maintains its film strength to protect engine components under heavy load and during intense operation.

High viscosity oils excel in preserving the protective oil film between engine components under elevated temperatures and heavy loads, preventing metal-to-metal contact and lessening wear.

Motor Oil Grades and Their Significance

Delving into the subject of motor oil grades, the Society of Automotive Engineers (SAE) has set a viscosity scale for motor and transmission oils, including multi grade oils. This helps in selecting the correct oil for an engine.

Reading the Labels: API and SAE Standards

But beyond SAE grades, how else can you select the right oil for your engine? One key component is understanding the American Petroleum Institute (API) Service Classification on the oil label. This classification indicates the oil’s suitability for various operating conditions and the ratio of its properties, beyond viscosity alone.

Selecting the Right Oil for Your Engine

You may wonder how to select the appropriate oil for your engine. The initial step is to consult your vehicle owner’s manual for specific viscosity grade recommendations, such as 5W-30 and 10W-30. This ensures the compatibility of the oil with the engine design and aids in preserving the engine’s warranty.

When to Opt for High Viscosity Oils

Sometimes, high viscosity oils are the best choice. For instance, they are crucial for older engines where they help maintain proper lubrication despite the wider clearances caused by engine wear and tear.

Vehicles that operate under heavy loads, such as trucks or those pulling heavy equipment, benefit from high viscosity oils due to their superior lubrication properties under extreme pressures.

The Case for Lower Viscosity Oils

On the other hand, lower-viscosity oil is recommended for newer cars due to enhanced fuel economy requirements and tighter engine clearances. The increased oil volume circulation provided by lower viscosity oils improves the oil’s cooling, cleaning, and lubricating abilities across all operating temperatures.

Monitoring and Maintaining Optimal Viscosity

The significance of regular oil checks and changes for preserving the engine’s optimal viscosity and averting breakdowns, which could result in expensive repairs, cannot be overstated.

The Impact of Oil Degradation on Viscosity

But what happens as oil ages? Over time, viscosity index improvers, especially those made with high molecular weight polymers, are prone to mechanical shear forces and become less effective. This, coupled with the fact that oil life expectancy is significantly reduced by half with every 10°C increase in base temperature, demonstrates managing proper viscosity is critical at high temperatures.

Viscosity Testing and Trend Analysis

Viscosity testing and trend analysis serve as indispensable tools in preserving engine health. Some common tests used to measure viscosity include:

ASTM D2270: Determines the viscosity index

ASTM D445: Determines viscosities at 40 and 100 degrees Celsius

ASTM D5481: Measures high-temperature, high-shear viscosity.

Summary

We’ve come a long way, from understanding what viscosity is to learning how to choose the right oil for your engine. Remember, the right viscosity can keep your engine running smoothly, prevent costly repairs, and extend the life of your vehicle.

Frequently Asked Questions

What is viscosity and how can it change?

Viscosity is the measure of a fluid’s resistance to flow. It can change based on the temperature, with higher temperatures generally leading to lower viscosity.

Is 5w30 thicker than 10w30?

Yes, 5W30 is generally thinner than 10W30 at below-freezing temperatures. The first number in the oil grade indicates its viscosity at cooler temperatures. So, 5W30 would flow better during an engine startup in winter or colder climates.

How is viscosity measured?

Viscosity is measured using a rotary viscometer, which rotates a spindle in the liquid and measures the torque required to do so. This method provides an accurate measurement of viscosity.

What are viscosity index improvers?

Viscosity index improvers are polymer additives that stabilize lubricant viscosity across temperatures without increasing base viscosity.

What is the difference between synthetic and conventional oils?

Synthetic oils provide better viscosity stability and performance across temperatures than conventional oils, as they are made from more advanced refining processes, resulting in higher purity and tailored molecular structures. This leads to better engine performance.